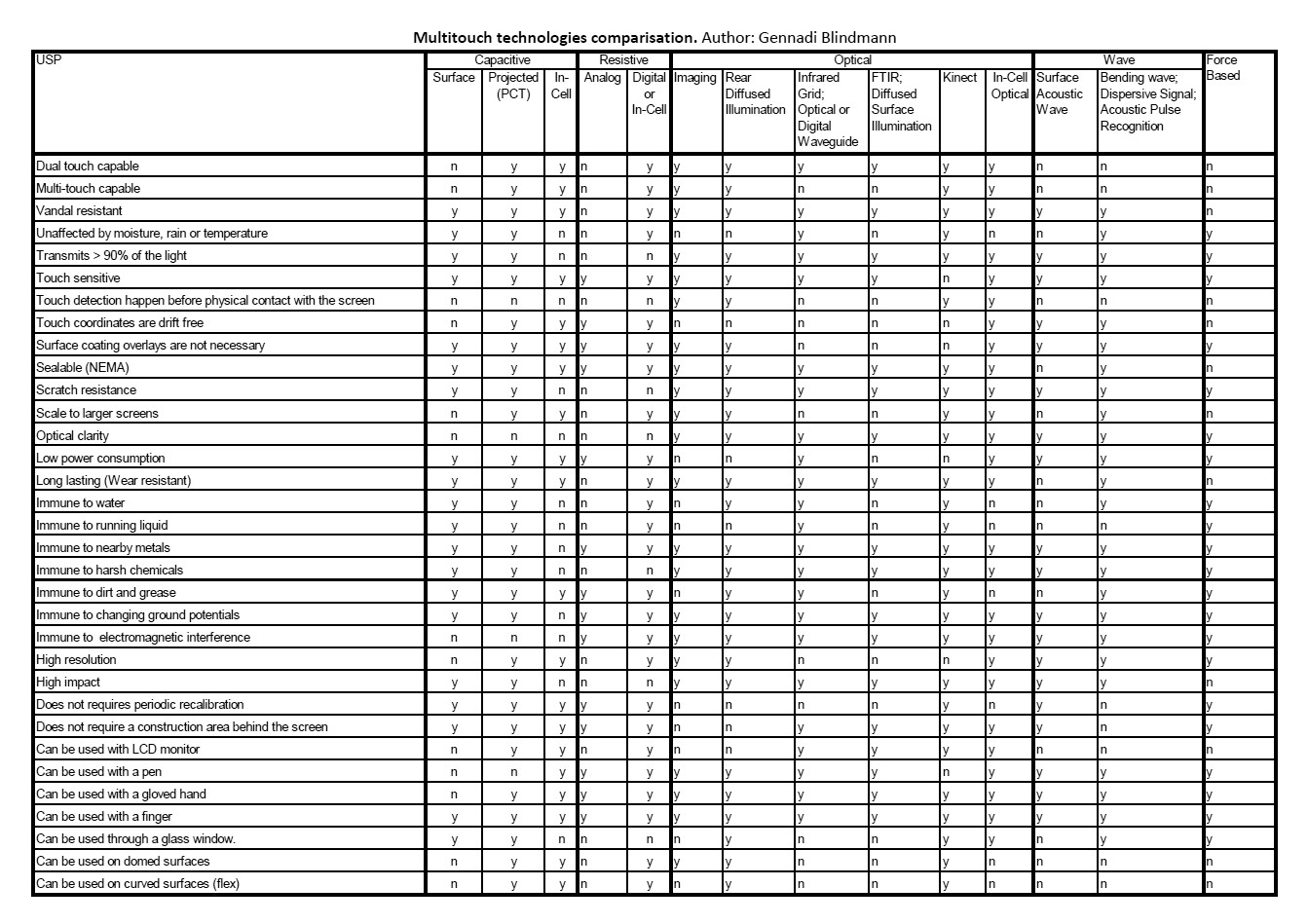

Knowledge base

Multitouch technologies

Digest author: Gennadi Blindmann

From physical point of view there are:

Capacitive Technology

• Surface Capacitive Technology

• Projected Capacitive Touch (PCT)

• In-cell: Capacitive

Resistive Technology

• Analog Resistive

• Digital Resistive (In-Cell: Resistive)

Optical technologies

• Optical Imaging / Infrared technology

• Rear Diffused Illumination (DI)

• Infrared Grid Technology (opto-matrix) / Digital Waveguide Touch (DWT)™ / Infrared Optical Waveguide

• Frustrated Total Internal Reflection (FTIR) / Diffused Surface Illumination (DSI)

• Kinect

• In-Cell: Optical

Wave Technologies

• Surface Acoustic Wave (SAW)

• Bending wave Technology (BWT)

Force-Based Sensing

1 Capacitive Technology

1.1 Surface Capacitive Technology

Surface Capacitive Technology

Surface Capacitive Technology

A capacitive touch screen panel consists of an insulator such as glass, coated with a transparent conductor. As the human body is also a conductor, touching the surface of the screen results in a distortion of the local electrostatic field, measurable as a change in capacitance.

In this basic technology, only one side of the insulator is coated with a conductive layer. A small voltage is applied to the layer, resulting in a uniform electrostatic field. When a conductor, such as a human finger, touches the uncoated surface, a capacitor is dynamically formed. The sensor’s controller can determine the location of the touch indirectly from the change in the capacitance as measured from the four corners of the panel.

Capacitive touchscreens provide: accurate drift free operation that is unaffected by temperature, humidity and can be operated by gloved fingers even in battery powered equipment.

Advantages:

• Touch sensitive

• Scratch resistance

• High impact

• Can be used through a glass window.

• Vandal resistant

• Immune to changing ground potentials

• Immune to nearby metals

• Immune to grease

• Immune to dirt

• Immune to water

• Immune to running liquid

• Immune to harsh chemicals

• Sealable (NEMA)

• Long lasting (Wear resistant)

• Transmits > 90% of the light

• Unaffected by moisture, rain or temperature

• Can be used with a finger

• Does not requires periodic recalibration

• Low power consumption

• Surface coating overlays are not necessary

• Does not require a construction area behind the screen

Disadvantages:

• Is not Dual touch capable

• Is not Multi-touch capable

• Cannot be used on curved surfaces (flex)

• Cannot be used on domed surfaces

• Low resolution

• Touch coordinates are not drift free

• Touch detection does not happen before physical contact with the screen

• Cannot be used with a gloved hand

• Cannot be scale to larger screens

• Cannot be used with LCD monitor

• Optical lack of clarity

• Cannot be used with a pen

• Cannot be used with a hard object

• Does not immune to electromagnetic interference

Touch functionality: Single touch

Product types:

• Glass window (integrated in glass sheet)

• Overlay frame

• Foil

1.2 Projected Capacitive Touch (PCT)

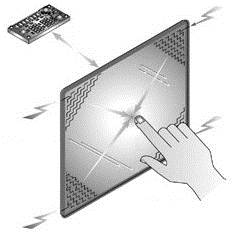

Projected Capacitive Touch

Projected Capacitive Touch

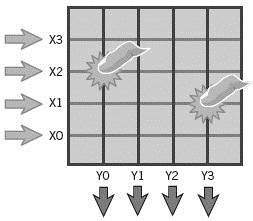

Projected Capacitive Touch: flow

Projected Capacitive Touch: flow

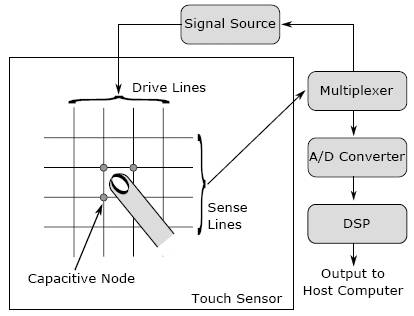

A PCT screen consists of an insulator such as glass or foil, coated with a transparent conductor – sensing (Copper, ATO, Nanocarbon or ITO). As the human finger (is also a conductor) touching the surface of the screen results in a distortion of the local electrostatic field, measurable as a change in capacitance.Now PCT used mutual capacitance, which is the more common projected capacitive approach and makes use of the fact that most conductive objects are able to hold a charge if they are very close together. If another conductive object, in this case a finger, bridges the gap, the charge field is interrupted and detected by the controller.

All PCT touch screens are made up of an electrode – a matrix of rows and columns. The capacitance can be changed at every individual point on the grid (intersection). It can be measured to accurately determine the exactly touch location.

All projected capacitive touch (PCT) solutions have three key features in common:

• Sensor as matrix of rows and columns

• Sensor lies behind the touch surface

• Sensor does not use any moving parts.

Applying voltage to the array creates a grid of capacitors.

Bringing a finger or conductive stylus close to the surface of the sensor changes the local electrostatic field, the electronic circuit sees a capacitor formed by the activated electrode “x” and the series facing electrode “y” with the capacity of the human body. Since the capacity of the human body is very great with respect to the capacity value of each capacitor formed of two electrodes “y” and “x”, the electronic circuit has approximately a capacity the value of which is that of the capacitor formed of the electrodes “y” and “x”, the capacity value of the human body being negligible in the calculation of the value of the total capacity.

By scanning with the assistance of the known electronic device the different pairs of capacitors and detecting the one having modified the natural frequency of an isolator which is associate therewith. To get an exact coordinate, the results from several row/column intersections are read and the counts used to triangulate the exact touch location.

This technology has the following variations:

The Near Field Imaging (NFI) instead of sensing the change in capacitance (like PCT) it looks for changes in an electrostatic field. The NFI system generates a weak modulated electrostatic field in the front layer of acryl or glass surface.

With an NFI capacitive touch screen, an electric field is created on conductive bars within the active portion of the touch screen. When an object, such as a user’s finger, comes in close proximity to the active area of the touch screen, it causes a modulation of the electric field, which is sensed by a controller connected to the conductive bars. By analyzing the modulation of the electric field, a location of the contact on the touch screen can be resolved.

NFI screen consist of two laminated glass sheets with a patterned coating of transparent metal oxide between them.

Comparison NFI and PCT:

• Touch resolution is slightly less

• Touch screens can be operated with a gloved hand

The Interactive Surface Technology (IST) is constructed of a flexible, polyester layer that can be laminated to the front or to the back of any surface, or applied to a contoured surface. The substrate for lamination can be Plexiglas, polycarbonate, plastic, glass, laminated glass or any other non-conductive surface. In addition, IST can support “on display” use with LCD panels or “off display” use creating touch pad or button interface designs not using a display.

Advantages:

• Touch sensitive

• Scratch resistance

• High impact

• Can be used through a glass window.

• Vandal resistant

• Immune to changing ground potentials

• Immune to nearby metals

• Immune to grease

• Immune to dirt

• Immune to water

• Immune to running liquid

• Immune to harsh chemicals

• Sealable (NEMA)

• Long lasting (Wear resistant)

• Transmits > 90% of the light

• Unaffected by moisture, rain or temperature

• Can be used with a finger

• Does not requires periodic recalibration

• Low power consumption

• Surface coating overlays are not necessary

• Does not require a construction area behind the screen

• Dual touch capable

• Multi-touch capable

• Can be used on curved surfaces (flex)

• Can be used on domed surfaces

• High resolution

• Touch coordinates are drift free

• Can be used with a gloved hand

• Scale to larger screens

• Can be used with LCD monitor

Disadvantages:

• Touch detection does not happen before physical contact with the screen

• Optical lack of clarity

• Cannot be used with a pen

• Cannot be used with a hard object

• Does not immune to electromagnetic interference

Touch functionality: Multi-touch

Product types:

• Glass window (integrated in glass sheet)

• Display solution

• Overlay frame

• Foil

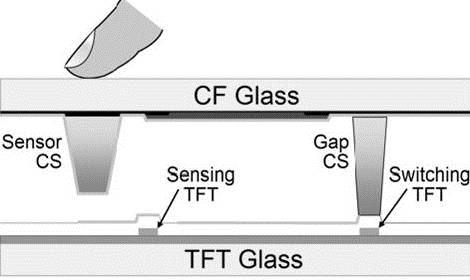

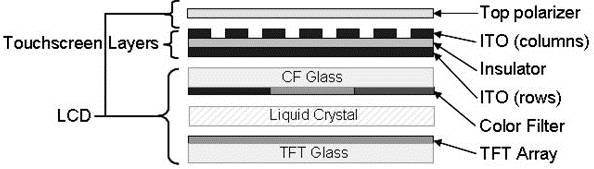

1.3 In-cell: Capacitive

ITO electrodes added inside the LCD cell (sometimes called “pressed capacitive”). Pressing the LCD changes the dielectric constant of the liquid crystal, which changes the capacitance between the electrodes.

Works with finger or stylus. Human body capacitance isn’t a factor.

In-cell Capacitive

In-cell Capacitive

On-cell:Projected-capacitive X-Y electrode array added on top of the color filter glass, under the top polarizer. It is the same as standard projected-capacitive.

It works only with finger, because human body capacitance changes mutual capacitance between electrodes. Cover-glass (~0.5 mm) can be added on top of polarizer to protect LCD surface.

On-cell Capacitive

On-cell Capacitive

Advantages:

• Touch sensitive

• Vandal resistant

• Immune to grease

• Immune to dirt

• Sealable (NEMA)

• Long lasting (Wear resistant)

• Can be used with a finger

• Does not requires periodic recalibration

• Low power consumption

• Surface coating overlays are not necessary

• Does not require a construction area behind the screen

• Dual touch capable

• Multi-touch capable

• Can be used on curved surfaces (flex)

• Can be used on domed surfaces

• High resolution

• Touch coordinates are drift free

• Can be used with a gloved hand

• Scale to larger screens

• Can be used with LCD monitor

• Can be used with a pen

• Can be used with a hard object

Disadvantages:

• Is not scratch resistance

• Is not high impact

• Cannot be used through a glass window.

• Is not immune to changing ground potentials

• Is not immune to nearby metals

• Is not immune to water

• Is not immune to running liquid

• Is not immune to harsh chemicals

• Transmits < 90% of the light

• Affected by moisture, rain or temperature

• Touch detection does not happen before physical contact with the screen

• Optical lack of clarity

• Does not immune to electromagnetic interference

Touch functionality: Multi-touch

Product types:

• LCD

2 Resistive Technology

2.1 Analog Resistive

Analog Resistive

Analog Resistive

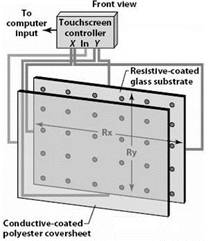

The resistive touchscreen is a contact-sensitive operating element, which consist from two glasses or plastic films (X and Y plate).

Each of them is coated with a transparent resistive and conductive layer of metal that are separated by dielectric spacers, for example by an air gap. Usually it is Indium Tin Oxide (ITO), Antimony Tin Oxide (ATO) or Carbon Nanotubes (Nanocarbon) like by PCT.

The X-plate is excited by the supply voltage. On touch, the two conductive plates come together and creating a resistor divider along the X-plate. The specific voltage at the point of contact, which represents the position on the X-plate, is sensed through the electrode on the Y-plate. The process is then repeated by exciting the Y-plate and sensing the Y position through the electrode on the X-plate.

On this way a touch controller senses the voltage changes in the “X” and “Y” direction. The controller sends a signal identifies the touch location to the Operation System (OS).

The resistive touchscreen can be operated by touching it lightly with your finger or stylus.

There exist 2 resistive touch panel constructions:

• Film to Glass = double layer of film and glass.

• Glass to Glass = double layer of glass and glass.

Advantages:

• Touch sensitive

• Immune to grease

• Immune to dirt

• Sealable (NEMA)

• Can be used with a finger

• Does not requires periodic recalibration

• Low power consumption

• Surface coating overlays are not necessary

• Does not require a construction area behind the screen

• Touch coordinates are drift free

• Can be used with a gloved hand

• Can be used with a pen

• Can be used with a hard object

• Immune to changing ground potentials

• Immune to nearby metals

• Immune to electromagnetic interference

Disadvantages:

• Is not vandal resistant

• Is not long lasting (Wear resistant)

• Is not Dual touch capable

• Is not Multi-touch capable

• Cannot be used on curved surfaces (flex)

• Cannot be used on domed surfaces

• Low resolution

• Cannot be scale to larger screens

• Cannot be used with LCD monitor

• Is not scratch resistance

• Is not high impact

• Cannot be used through a glass window.

• Is not immune to water

• Is not immune to running liquid

• Is not immune to harsh chemicals

• Transmits < 90% of the light

• Affected by moisture, rain or temperature

• Touch detection does not happen before physical contact with the screen

• Optical lack of clarity

Touch functionality: Single touch

Product types:

• Overlay frame

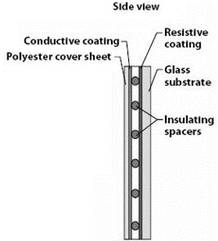

2.2 Digital Resistive (In-Cell: Resistive)

Digital Resistive. Layers

Digital Resistive. Layers

Digital Resistive technology pressing LCD surface closes micro-switches in each pixel and uses a pre-determined specific touch area (cell). Several x axis electrodes are specified on the upper X-plate and Y axis electrodes on the lower Y-plate. Junctions of the X axis and Y axis electrodes form specific cells (touch areas) for use as input button. Digital Resistive technology responds with Yes/No signals like a switch, determining whether upper and lower electrodes are connected. The upper and lower electrodes will be connected by pressure if user touched this area. The Digital Resistive technology consists from two layers, each with a conductive coating on the interior surface. Special dielectric (“Insulating”) spacers are distributed evenly across the active area and separate 2 conductive interior layers: conductive and resistive coating. The pressure from using finger or stylus produces an internal electrical contact at the touch point which supplies the controller with vertical and horizontal analog voltages for data input.

Digital Resistive. Front view |

Digital Resistive: Site view |

In-Cell: Resistive technology has the similar principle as emerging “digital resistive” touch technology.

In-Cell: Resistive

In-Cell: Resistive

Advantages:

• Touch sensitive

• Immune to grease

• Immune to dirt

• Sealable (NEMA)

• Can be used with a finger

• Does not requires periodic recalibration

• Low power consumption

• Surface coating overlays are not necessary

• Does not require a construction area behind the screen

• Touch coordinates are drift free

• Can be used with a gloved hand

• Can be used with a pen

• Can be used with a hard object

• Immune to changing ground potentials

• Immune to nearby metals

• Immune to electromagnetic interference

• Vandal resistant

• Long lasting (Wear resistant)

• Dual touch capable

• Multi-touch capable

• Can be used on curved surfaces (flex)

• Can be used on domed surfaces

• High resolution

• Scale to larger screens

• Can be used with LCD monitor

• Immune to water

• Immune to running liquid

• Unaffected by moisture, rain or temperature

Disadvantages:

• Is not scratch resistance

• Is not high impact

• Cannot be used through a glass window.

• Is not immune to harsh chemicals

• Transmits < 90% of the light

• Touch detection does not happen before physical contact with the screen

• Optical lack of clarity

Touch functionality: Multi-touch

Product types:

• LCD

• Display solution

• Overlay frame

• Foil

Optical technologies

3 Optical technologies

3.1 Optical Imaging / Infrared technology

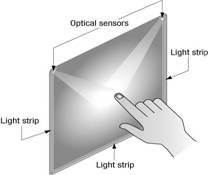

Optical Imaging

Optical Imaging

Multiple optical sensors track the movement of an object close to the surface by detecting the interruption or reflection of (IR) light source, which is emitted in a plane across the display surface and can be either active (IR LED) or passive (special reflective surfaces).

The (IR) light source and optical sensors of the touch screen are synchronized using a sophisticated algorithm that also reduces the effect of ambient light, thus creating a very clear, accurate touch selection.Touch occurs when a finger or object interrupt or reflected the light from the cameras. The controller board received signals from the optical sensors, compensates for optical distortions and triangulates the position (X,Y coordinates) of the touching object with extreme accuracy. Optical imaging technology provides touch sensitivity over the whole screen.

Advantages:

• Touch sensitive

• Sealable (NEMA)

• Can be used with a finger

• Surface coating overlays are not necessary

• Can be used with a gloved hand

• Can be used with a pen

• Can be used with a hard object

• Immune to changing ground potentials

• Immune to nearby metals

• Immune to electromagnetic interference

• Vandal resistant

• Long lasting (Wear resistant)

• Dual touch capable

• Multi-touch capable

• Can be used on domed surfaces

• High resolution

• Scale to larger screens

• Scratch resistance

• High impact

• Immune to harsh chemicals

• Transmits > 90% of the light

• Touch detection happen before physical contact with the screen

• Optical clarity

Disadvantages:

• Is not immune to grease

• Is not immune to dirt

• Requires periodic recalibration

• Hight power consumption

• Require a construction area behind the screen

• Touch coordinates are not drift free

• Cannot be used on curved surfaces (flex)

• Cannot be used with LCD monitor

• Is not immune to water

• Is not immune to running liquid

• Affected by moisture, rain or temperature

• Cannot be used through a glass window.

Touch functionality: Dual touch*

Product types:

• Overlay frame

• Display solution

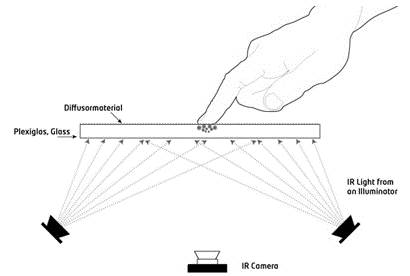

3.2 Rear Diffused Illumination (DI)

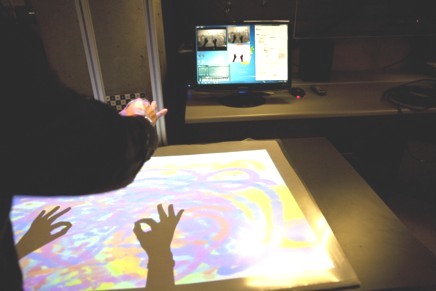

The Rear Diffused Illumination touch technology uses fact, that Infrared light is shone from the opposite side of the touch surface. When an object interrupted the infrared light it reflects the light back to the camera and creating a blob. An infrared camera is pointed at the touch surface and detects when fingers touch the surface. Infrared light is used to distinguish between a visual image on the touch surface and the fingers being tracked. The camera is connected to a computer and a tracking driver uses the camera image to track and create touch coordinates.

Rear Diffused Illumination

Rear Diffused Illumination

Advantages:

• Touch sensitive

• Sealable (NEMA)

• Can be used with a finger

• Surface coating overlays are not necessary

• Can be used with a gloved hand

• Can be used with a pen

• Can be used with a hard object

• Immune to changing ground potentials

• Immune to nearby metals

• Immune to electromagnetic interference

• Vandal resistant

• Long lasting (Wear resistant)

• Dual touch capable

• Multi-touch capable

• Can be used on domed surfaces

• High resolution

• Scale to larger screens

• Scratch resistance

• High impact

• Immune to harsh chemicals

• Transmits > 90% of the light

• Touch detection happen before physical contact with the screen

• Optical clarity

• Immune to grease

• Immune to dirt

• Can be used on curved surfaces (flex)

• Immune to water

• Can be used through a glass window.

Disadvantages:

• Requires periodic recalibration

• Hight power consumption

• Require a construction area behind the screen

• Touch coordinates are not drift free

• Cannot be used with LCD monitor

• Is not immune to running liquid

• Affected by moisture, rain or temperature

Touch functionality: Multi-touch

Product types:

• Overlay frame

• Display solution

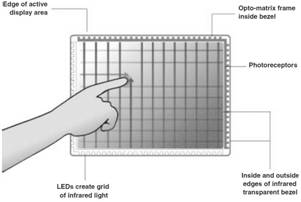

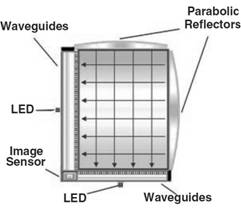

3.3 Infrared Grid Technology (opto-matrix) / Digital Waveguide Touch (DWT)™ / Infrared Optical Waveguide

Infrared Grid Technology (opto-matrix)

Digital Waveguide Touch (DWT)™

Digital Waveguide Touch (DWT)™

The same Opto-Matrix technique is used by Infrared Grid, Digital Waveguide Touch (DWT)™ and Infrared Optical Waveguide technologies.Opto-Matrix relies on the interruption of an IR light grid in front of the display screen. The touch (opto-matrix) frame contains a row of IR-light emitting diodes (LEDs) and photo transistors. Each mounted on two opposite sides to create a grid of invisible infrared light. The frame assembly is comprised of PCBs on which the opto-electronics are mounted and are concealed behind an IR-transparent bezel which shields the opto’s from the operating environment whilst allowing the IR beams to pass through. When touching the screen one or more of the beams are obstructed resulting in an X and a Y coordinate being sent to the control electronics to indicate the exact touch point.DWT is based on the interruption of invisible light beams and needs no touch panel overlay.

Advantages:

• Touch sensitive

• Sealable (NEMA)

• Can be used with a finger

• Can be used with a gloved hand

• Can be used with a pen

• Can be used with a hard object

• Immune to changing ground potentials

• Immune to nearby metals

• Immune to electromagnetic interference

• Vandal resistant

• Long lasting (Wear resistant)

• Dual touch capable

• Scratch resistance

• High impact

• Immune to harsh chemicals

• Transmits > 90% of the light

• Optical clarity

• Immune to grease

• Immune to dirt

• Immune to water

• Low power consumption

• Does not require a construction area behind the screen

• Can be used with LCD monitor

• Immune to running liquid

• Unaffected by moisture, rain or temperature

Disadvantages:

• Surface coating overlays are necessary

• Is not Multi-touch capable

• Cannot be used on domed surfaces

• Low resolution

• Cannot be scale to larger screens

• Touch detection does not happen before physical contact with the screen

• Cannot be used on curved surfaces (flex)

• Cannot be used through a glass window.

• Requires periodic recalibration

• Touch coordinates are not drift free

Touch functionality: Dual touch*

Product types:

• Overlay frame

• Display solution

3.4 Frustrated Total Internal Reflection (FTIR) / Diffused Surface Illumination (DSI)

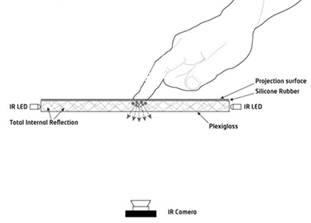

Frustrated Total Internal Reflection (FTIR)

Frustrated Total Internal Reflection (FTIR)

The same method is used by Frustrated Total Internal Reflection (FTIR) and Diffused Surface Illumination (DSI).This method uses this to great effect, flooding the inside of a piece of acrylic with infrared light by trapping the light rays within the acrylic using the principle of Total Internal Reflection. Total internal reflection is an optical phenomenon that happens when a ray of light strikes a medium boundary at an angle larger than a particular critical angle with respect to the normal to the surface. If the refractive index is lower on the other side of the boundary, no light can pass through and all of the light is reflected. When the user comes into contact with the surface, the light rays are said to be frustrated, since they can now pass through into the contact material (usually skin), and the reflection is no longer total at that point. In case DSI special acrylic uses small particles that are inside the material, acting like thousands of small mirrors. When you shine IR light into the edges of this material, the light gets redirected and spread to the surface of the acrylic.

Advantages:

• Touch sensitive

• Sealable (NEMA)

• Can be used with a finger

• Can be used with a gloved hand

• Can be used with a pen

• Can be used with a hard object

• Immune to changing ground potentials

• Immune to nearby metals

• Immune to electromagnetic interference

• Vandal resistant

• Long lasting (Wear resistant)

• Dual touch capable

• Scratch resistance

• High impact

• Immune to harsh chemicals

• Transmits > 90% of the light

• Optical clarity

• Does not require a construction area behind the screen

• Can be used with LCD monitor

Disadvantages:

• Is not immune to grease

• Is not immune to dirt

• Is not immune to water

• Hight power consumption

• Is not immune to running liquid

• Affected by moisture, rain or temperature

• Surface coating overlays are necessary

• Is not Multi-touch capable

• Cannot be used on domed surfaces

• Low resolution

• Cannot be scale to larger screens

• Touch detection does not happen before physical contact with the screen

• Cannot be used on curved surfaces (flex)

• Cannot be used through a glass window.

• Requires periodic recalibration

• Touch coordinates are not drift free

Touch functionality: Multi-Touch

Product types:

• Overlay frame

• Display solution

3.5 Kinect

Kinect

Kinect

Kinect uses near-infrared transmitter to create a pattern of near-infrared dots. The distortion of this pattern and measurement of time it takes to reflect each ray from the objects in space allows creating a precise depth map of the space in front of the camera. The changes to the map are updated 30 times per second and allow precise movement detection, face recognition, and feature extraction. It is important here to specify what “precise” means in the preceding description. Kinect is able to “see” object 1.2-3.5 meters from the camera, with limited perception in the range of 0.7 to 6 meters. The view is 57º horizontally and 43º vertically. The depth map is accurate to about 1cm. Picture 23: Kinect

These measurements clearly show that the motion and gesture detection using Kinect simply would not work on a surface of a spherical screen as the precision is not high enough and the view of the camera is too narrow for a half-sphere screen.

Advantages:

• Sealable (NEMA)

• Can be used with a finger

• Can be used with a gloved hand

• Immune to changing ground potentials

• Immune to nearby metals

• Immune to electromagnetic interference

• Vandal resistant

• Long lasting (Wear resistant)

• Dual touch capable

• Scratch resistance

• High impact

• Immune to harsh chemicals

• Transmits > 90% of the light

• Optical clarity

• Does not require a construction area behind the screen

• Can be used with LCD monitor

• Immune to grease

• Immune to dirt

• Immune to water

• Immune to running liquid

• Unaffected by moisture, rain or temperature

• Multi-touch capable

• Can be used on domed surfaces

• Scale to larger screens

• Touch detection happen before physical contact with the screen

• Can be used on curved surfaces (flex)

• Can be used through a glass window.

• Does not requires periodic recalibration

Disadvantages:

• Is not touch sensitive

• Cannot be used with a pen

• Cannot be used with a hard object

• Hight power consumption

• Surface coating overlays are necessary

• Low resolution

• Touch coordinates are not drift free

Touch functionality: Multi-Touch

Product types:

• LCD

• Display solution

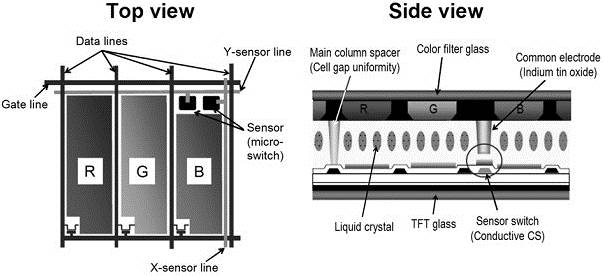

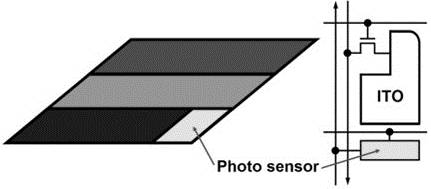

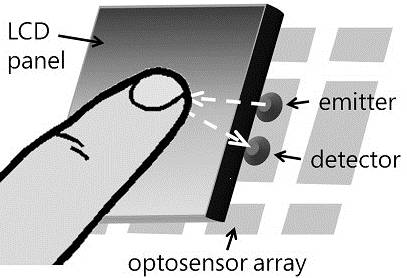

3.6 In-Cell: Optical

In-Cell Optical

In-Cell Optical Array

Photo-sensor in each pixel or group of pixels sees shadow of finger in bright light or reflection of backlight on finger in dim light.

A key element in the construction is a device known as a retro-reflective optosensor. This is a sensing element which contains two components: a light emitter and an optically isolated light detector. It is therefore capable of both emitting light and, at the same time, detecting the intensity of incident light. If a reflective object is placed in front of the optosensor, some of the emitted light will be reflected back and will therefore be detected.It is based around a 2D grid of retro-reflective optosensors which are placed behind an LCD panel. Each optosensor emits light that passes right through the entire panel. Any reflective object in front of the display (such as a fingertip) will reflect a fraction of the light back, and this can be detected. By using a suitable grid of retro-reflective optosensors distributed uniformly behind the display it is therefore possible to detect any number of fingertips on the display surface. The raw data generated is essentially a low resolution grey scale “image” of what can be seen through the display in the infrared spectrum. By applying computer vision techniques to this image, it is possible to generate information about the number and position of multiple touch points.

An array of retro-reflective optosensors is placed behind an LCD. Each of these contains two elements: an emitter which shines IR light through the panel; and a detector which picks up any light reflected by objects such as fingertips in front of the screen.A critical aspect of this technology is the use of retro-reflective sensors that operate in the infrared part of the spectrum, for a number of reasons:- Although IR light is attenuated by the layers in the LCD panel, some still passes right through the display.This is unaffected by the displayed image.- A human fingertip typically reflects around 20% of incident IR light and is therefore a quite passable ‘reflective object’.- IR light is not visible to the user, and therefore doesn’t detract from the image being displayed on the panel.

Advantages:

• Sealable (NEMA)

• Can be used with a finger

• Can be used with a gloved hand

• Immune to changing ground potentials

• Immune to nearby metals

• Immune to electromagnetic interference

• Vandal resistant

• Long lasting (Wear resistant)

• Dual touch capable

• Scratch resistance

• High impact

• Immune to harsh chemicals

• Transmits > 90% of the light

• Optical clarity

• Does not require a construction area behind the screen

• Can be used with LCD monitor

• Multi-touch capable

• Scale to larger screens

• Touch detection happen before physical contact with the screen

• Can be used through a glass window.

• Touch sensitive

• Can be used with a pen

• Can be used with a hard object

• Low power consumption

• Surface coating overlays are not necessary

• High resolution

• Touch coordinates are drift free

Disadvantages:

• Is not immune to grease

• Is not immune to dirt

• Is not immune to water

• Is not immune to running liquid

• Affected by moisture, rain or temperature

• Cannot be used on domed surfaces

• Cannot be used on curved surfaces (flex)

• Requires periodic recalibration

Touch functionality: Multi-Touch

Product types:

• LCD

4 Wave Technologies

4.1 Surface Acoustic Wave (SAW)

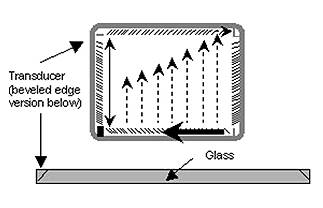

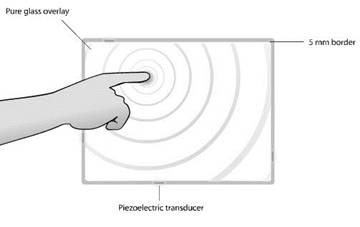

Surface Acoustic Wave (SAW)

Surface Acoustic Wave (SAW)

Surface Acoustic Wave (SAW) touch technology uses fact, that the waves are spread across the screen by bouncing off reflector arrays along the edges of the overlay and are detected by two “receivers”. The coordinates are then determined by the controller circuitry that measures the time at which the amplitude declines. Piezoelectric transmitters on the sensor generate acoustic waves on the surface on alternating X-axis and Y-axis patterns. This waves are reflected by a pattern of edge ridges directing the energy to piezoelectric receivers. A touch to the surface of the sensor causes attenuation to a part of the wave corresponding to touch position. Touch location is based on the time delay from the transmitted pulse to the center of the attenuation area of the wave.

Advantages:

• Can be used with a finger

• Can be used with a gloved hand

• Immune to changing ground potentials

• Immune to nearby metals

• Immune to electromagnetic interference

• Vandal resistant

• Scratch resistance

• High impact

• Immune to harsh chemicals

• Transmits > 90% of the light

• Optical clarity

• Does not require a construction area behind the screen

• Touch sensitive

• Can be used with a pen

• Can be used with a hard object

• Low power consumption

• Surface coating overlays are not necessary

• High resolution

• Touch coordinates are drift free

• Does not requires periodic recalibration

Disadvantages:

• Is not sealable (NEMA)

• Is not long lasting (Wear resistant)

• Is not Dual touch capable

• Cannot be used with LCD monitor

• Is not Multi-touch capable

• Cannot be scale to larger screens

• Touch detection does not happen before physical contact with the screen

• Cannot be used through a glass window.

• Is not immune to grease

• Is not immune to dirt

• Is not immune to water

• Is not immune to running liquid

• Affected by moisture, rain or temperature

• Cannot be used on domed surfaces

• Cannot be used on curved surfaces (flex)

Touch functionality: Single-Touch

Product types:

• Overlay frame

• Display solution

4.2 Bending wave Technology (BWT)

Bending wave

Bending wave

The same Bending wave technique is used by Acoustic Pulse Recognition (APR) touch and by Dispersive Signal Touch (DST).

Bending wave (BWT) works by recognizing the vibrations created when the surface is touched and based by measuring the mechanical energy (bending waves) within a substrate created by touch of surface. When the touch implement impacts the surface, bending waves are induced that radiate away from the touch location. As the wave travels outwards, the signal spreads out over time due to the phenomena of dispersion.Piezoelectric sensors positioned in the corners on the backside of the surface convert this smeared mechanical impulse into an electrical signal.

Initial Touch Contact |

Progressing Dispersion with the Beginning of Reflection Effects Down |

Highly Complex Dispersion Pattern with Reflections |

Post-Algorithm Pattern |

The further away the touch point is from the sensor, the more the signal is smeared. The “smeared” signals are then interpreted by a complex set of algorithms to precisely pinpoint the exact touch location on the screen.BWT is a passive technology, waiting for a signal created by a touch impact. The sophisticated and optimized controller that continuously monitors for a touch impact.

Advantages:

• Can be used with a finger

• Can be used with a gloved hand

• Immune to changing ground potentials

• Immune to nearby metals

• Immune to electromagnetic interference

• Vandal resistant

• Scratch resistance

• High impact

• Immune to harsh chemicals

• Transmits > 90% of the light

• Optical clarity

• Touch sensitive

• Can be used with a pen

• Can be used with a hard object

• Low power consumption

• Surface coating overlays are not necessary

• High resolution

• Touch coordinates are drift free

• Sealable (NEMA)

• Long lasting (Wear resistant)

• Scale to larger screens

• Can be used through a glass window.

• Immune to grease

• Immune to dirt

• Immune to water

• Unaffected by moisture, rain or temperature

Disadvantages:

• Require a construction area behind the screen

• Requires periodic recalibration

• Is not Dual touch capable

• Cannot be used with LCD monitor

• Is not Multi-touch capable

• Touch detection does not happen before physical contact with the screen

• Is not immune to running liquid

• Cannot be used on domed surfaces

• Cannot be used on curved surfaces (flex)

Touch functionality: Single-Touch

Product types:

• Overlay

5 Force-Based Sensing

Force-Based Sensing

Force-Based Sensing

The basic operational principle is a calculating the touch coordinates of the applied force of a user’s touch or gesture. The force based touch technologies applied touch force is used for determining the touch coordinates. Controller will, and must, also accurately know the magnitude of the user’s touch at any given moment of time. The system output is therefore based on 3-variables; x- and y-coordinates and the “z-coordinate” (force level).

The technical design of a force based touch system must allow for a close-to-frictionless movement in the perpendicular to x-y plane (the z-plan) to ensure that the complete force (F) of the touch is directly transferred to the force sensors.For example: a system based on four sensors S1,S2,S3,S4 has the touch force F = FS1 + FS2 + FS3 + FS4. As the location of the four force sensors is known, the exact coordinates of the touch coordinates can easily be calculated. Interfering forces can be allowed (like by other technologies) for, as long as they are known, repeatable and can be compensated for.

Advantages:

• Can be used with a finger

• Can be used with a gloved hand

• Immune to changing ground potentials

• Immune to nearby metals

• Immune to electromagnetic interference

• Scratch resistance

• Immune to harsh chemicals

• Transmits > 90% of the light

• Optical clarity

• Touch sensitive

• Can be used with a pen

• Can be used with a hard object

• Low power consumption

• Surface coating overlays are not necessary

• High resolution

• Can be used through a glass window.

• Immune to grease

• Immune to dirt

• Immune to water

• Unaffected by moisture, rain or temperature

• Does not require a construction area behind the screen

• Does not requires periodic recalibration

• Immune to running liquid

Disadvantages:

• Is not vandal resistant

• Is not high impact

• Touch coordinates are not drift free

• Is not sealable (NEMA)

• Is not long lasting (Wear resistant)

• Cannot be scale to larger screens

• Is not Dual touch capable

• Cannot be used with LCD monitor

• Is not Multi-touch capable

• Touch detection does not happen before physical contact with the screen

• Cannot be used on domed surfaces

• Cannot be used on curved surfaces (flex)

Touch functionality: Single-Touch

Product types:

• Overlay

Multitouch Comparisation

English

English  Русский

Русский